2016 Cadillac CT6 Summary and Highlights

Cadillac is going to debut its brand-new CT6 full-size luxury sedan flagship in the upcoming 2015 NY auto show. Today, information regarding the CT6 is released before the official debut event. The most important news is the all-new 3.0L twin-turbo, and another new 3.6L naturally aspirated engine. In this article, we will first quickly go over the highlights, and then provide a short analysis on this new 3.0L turbo V6 engine.

Above image: the Cadillac CT6 sedan in a teaser video

Highlights about the Cadillac CT6:

– 3.0L twin-turbo DOHC V6 engine, 400hp@5,500RPM, with 400 lb-ft@2,500-5,000RPM; manifold-integrated water-to-air intercooler; maximum boost pressure: 125 kPa

– 3.6L naturally aspirated V6, 335hp@6,800RPM, 284 lb-ft@5,300RPM

– 8-speed automatic transmission; GM 8L90 (for the 3.0TT) and 8L45 (for the 3.6L NA)

– 64% of the car body material is aluminum

Above is all the information we have so far. Since our interests is on this new 3.0 twin-turbo engine, in the following we will examine it in detail.

Why Use 3.0L Displacement?

First let us focus on this question: why Cadillac wants to develop this 3.0L twin-turbo engine? Why not use the existing 3.6L twin-turbo one?

From the technical standpoint, the current 3.6L twin-turbo engine (used on the CTS VSport) has higher output, and their weight difference is negligible considering the total curb weight of the CT6. Therefore it should be a better choice to put the 3.6 twin-turbo engine in the CT6. But why GM still decided to use the 3.0L instead?

Some may say it’s because better fuel efficiency and higher MPG. While this factor may be important for cars at lower price range, we have never heard any previous examples that a full-size luxury sedan’s success was hampered just because its fuel efficiency is 1-2 MPG lower than others. On the other hand, since the 3.0L TT has more advanced technologies, GM could have applied these new technologies into the 3.6L TT, to get even higher output (an upgraded version of the current 3.6L TT V6).

The real reason behind Cadillac’s decision is not in the technical aspect. In fact, if you have read our previous report about Cadillac’s plan for the next 3 years, you will know: the Chinese market is what the GM senior management care most at this moment.

Chinese regulation taxes automobiles by the engine displacement. Simply speaking, anything over 3.0L will be taxed heavily in China. This is the major factor that prompts GM to pick the 3.0 as the magic number. In fact, GM is not the first one that have done this; Porsche also developed a 3.0L twin-turbo V6 while it already has the 3.6L one.

The 3.6L vs. 3.0L Version

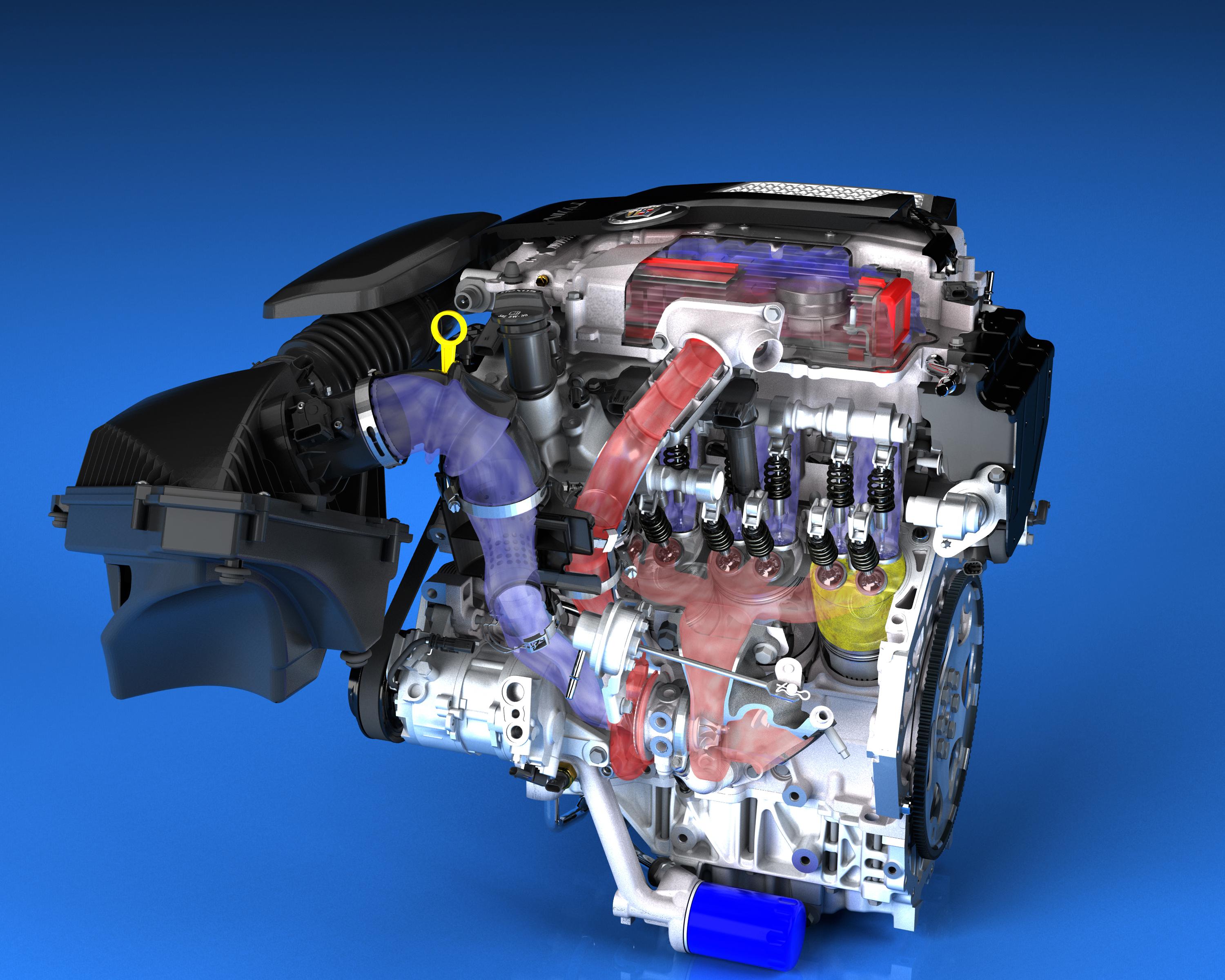

Above image: the GM 3.0L twin-turbo V6 engine to be used on the Cadillac CT6

Interested in our exclusive Cadillac CT6 analysis? You may like our other articles:

The Hot Hatch War Begins: 2016 Focus RS, WRX STI, Golf R

AWD System Dissected: Audi Quattro vs. Volkswagen 4Motion

Why The Lexus LFA Is A Special Supercar

Now back to the technical side. Generally speaking, this new 3.0L TT engine is based on the GM LF3 family, with multiple enhancements added. The image below shows the 3.6L twin-turbo V6 currently used on the Cadillac CTS VSport. You can see both the 3.0L and the 3.6L version have very similar structure and construction, including the integrated exhaust manifold, and also the manifold-integrated water-to-air intercooler.

Above image: the GM 3.6L twin-turbo V6 engine used on the Cadillac CTS VSport

GM LF3 3.0L Twin-Turbo V6 Advantages

With the current available information, the 3.0L TT V6 is the best in its class. Reasons are:

1. The LF3 engine family has manifold-integrated water-to-air intercooler, which significantly shortened the length of the intake path, therefore it has much better throttle response;

2. It is not only the first turbo V6 to use cylinder deactivation, but also the only 6-cylinder engine (including both forced-induction and naturally aspirated) that deactivates itself into the V4 mode. Common cylinder deactivation practice in the industry is to turn the engine into the I3 mode (only 3 cylinders are working); Honda has experimented the V4 mode approach initially, but they gave up later on. The reason why use the V4 mode and not the I3 mode for the CT6, is because the sedan’s heavier weight requires relatively higher power even during cruising; I3 mode for the 3.0L displacement is similar to a 1.5L engine, which is too weak for this application.

3. By carefully reading the press release, you will see a paragraph beginning with this sentence: “new four-cam phasing system…”. You may think it is just describing the VVT feature, however it is not that simple. Have you heard of some recent news that Toyota has developed an fuel-saving technology, which enables an internal combustion engine to switch between the Atkinson cycle and the traditional Otto cycle mode (The Lexus RC-F/GS-F 5.0 V8, and the 2016 Tacoma’s 3.5L V6 all use this technology)? In fact, what GM has written here means exactly the same stuff.

Generally speaking, this GM 3.0L twin-turbo engine has used almost all latest fuel-saving technologies one can think of.

4. Peak torque (with displacement and boost pressure) represents an engine’s volumetric efficiency. The GM engine uses a 1.25 bar boost to get 400 lb-ft from a 3.0L displacement. This is a first class achievement. Comparing this to other similar engines: the 3.0L turbo V6 on the current Porsche Panamera S, uses 1.2 bar boost to generate 384 lb-ft; also the BMW S55 (used on the current M3 and M4) gets 406 lb-ft out of the same 3.0L displacement using a slightly-higher 1.3 bar boost.

Above image: Cutaway illustration of the 3.0L twin-turbo engine

5. The layout and packaging of the GM LF3 turbo V6 engine is superb – this includes both the current 3.6L TT and also the upcoming 3.0L TT engine. For example, its exhaust manifold is integrated into the cylinder head, which makes it possible for the turbocharger to locate as close as possible to the cylinder block – this layout is much better than the Ford 3.5L EcoBoost V6, whose turbochargers are placed more outward and take extra spaces in the engine bay (see the below image, showing the Ford 3.5L EcoBoost V6, notice the turbocharger is sticking out from the cylinder bank, and the image even has not included the bulky intercooler).

Above image: Ford 3.5L EcoBoost V6 (intercooler not included)

In the turbocharged LF3-family engine, two water-to-air intercoolers are placed between the cylinder V-bank; they also form a pressure stabilizing chamber, and the throttle body is integrated into this chamber as well. This is a brilliant design since it takes much less spaces to do more things (cooling the intake air, stabilizing the air pressure, modulating the air flow volume). Therefore, the LF3 is a very compact design: despite the fact that it’s a mid-size displacement V6 engine with two turbochargers, its packaging size is similar to a small-displacement naturally aspirated V6 engine. At this moment, the GM LF3 turbo V6 is the most compact turbo V6 engine in the industry.

Again, below is the cutaway of the 3.6L twin-turbo version, from there you can see they both share many LF3 family features.

Above image: Cutaway illustration of the 3.6L twin-turbo engine, similar to the latest 3.0L version

Why Making The 3.6L before The 3.0L Version?

The last question we ask is: if the new 3.0L is so good, why GM did not directly design/make and put it in the current CTS VSport? The previous 3.6L version seems to be overlapping with this new 3.0L version.

Main reason for this is: it took GM some time to fine-tune the turbo/intake/exhaust systems (in order to achieve optimum output); GM also needs time to figure out the cylinder deactivation feature, and also the Atkinson cycle/Otto cycle automatic switching functionality. Therefore, the 3.6L was born to fill in the time gap, creating value to customer during the period that GM is working on the new features for the new 3.0L engine.

It is also highly possible that GM is planning to gradually replace the current 3.6L TT V6 with this new 3.0L version.

At last, if you are interested, please see the below press release for more details.

[expand title=”Click to view press release”]

Cadillac Next-Gen V-6 Engines Led by 3.0L Twin Turbo

Segment-leading power, efficiency in world’s most advanced six-cylinder

DETROIT – Cadillac today announced a new generation of V-6 engines, led by an exclusive Twin Turbo V-6 that will be one of the industry’s most advanced six-cylinder gasoline engines. It leverages the latest technology to balance efficiency, performance and refinement in the upcoming, top-of-the-range CT6 luxury performance sedan.

The all-new Cadillac 3.0L Twin Turbo is designed to achieve new thresholds of refinement and specific output for the brand’s new prestige luxury sedan, which makes its world premiere March 31, at the New York International Auto Show. Production begins late this year at General Motors’ Detroit-Hamtramck Assembly Plant.

Peak output is estimated at 400 horsepower (298 kW) and 400 lb-ft of torque (543 Nm), making it one of the most power-dense V-6 DOHC engines in the world, developing 133 horsepower (99 kW) per liter.

The 3.0L Twin Turbo is the only six-cylinder engine to combine turbocharging with cylinder deactivation and stop/start technologies to conserve fuel. Cadillac expects the combination to enhance fuel economy by up to an estimated 6 percent. Cylinder deactivation temporarily deactivates two of the cylinders in light-load driving conditions to enhance efficiency and seamlessly reactivates them when the driver demands full power.

With the stop/start system, the 3.0L Twin Turbo is shut down in certain driving conditions such as stop-and-go city driving to reduce fuel consumption, automatically restarting when the driver takes his or her foot off the brake pedal.

“Cadillac’s elevation on the world stage is driven in great part by its advanced powertrain technology and the all-new 3.0L Twin Turbo powers past the traditional segment leaders with higher degrees of the performance and refinement their reputations were built on,” said Rich Bartlett, assistant chief engineer.

The highly-acclaimed Hydra-Matic 8L90 eight-speed automatic transmission transfers the 3.0L Twin Turbo’s power to the CT6.

Similar to the turbo system in the track-capable Cadillac ATS-V, the new 3.0L Twin Turbo features turbochargers with lightweight, low-inertia titanium-aluminide turbine wheels and an efficient, patented low-volume charge-air cooler, which contribute to optimal boost production and more immediate power delivery.

The advanced, low-inertia turbochargers enable the engine to sustain peak torque from 2,500 rpm to 5,000 rpm, giving it a broad torque curve that is conveyed to the driver through a feeling of responsive, sustained power across the entire rpm band.

“Torque is the pulling power of an engine and the new 3.0L Twin Turbo delivers it with confidence-inspiring smoothness and progression,” said Bartlett. “In fact, the potency of the torque across the rpm band is matched only by the satisfaction of the horsepower created as those revs climb quickly to 6,500 rpm.”

The 3.0L Twin Turbo’s estimated 400 horsepower and 133 hp per liter is 27 percent greater than the BMW 740Li’s 3.0L twin-turbo V-6 (315 hp and 105 hp/L) and 29 percent more than the Audi A7’s 3.0L supercharged V-6 (310 hp and 103 hp/L).

All-new architecture

Cadillac’s new 3.0L Twin Turbo is part of a new generation of technologically advanced V-6 engines, which includes a new version of the award-winning 3.6L naturally aspirated engine employed for years across the brand’s model range. Each features all-new structural and combustion elements designed to complement higher performance and greater efficiency with exceptional quietness and smoothness.

The 3.0L Twin Turbo is up to 5 dB quieter than the Audi 3.0L TFSI engine, while the 3.6L is up to 4 dB quieter than the Infiniti 3.7L V-6.

Features shared by the 3.0L Twin Turbo and 3.6L include:

• Stronger, stiffer aluminum block with increased structure in the bulkheads for superior rigidity

• Tough, refined rotating assembly with a stiff forged-steel crankshaft, friction-reducing polymer-coated pistons and strong high-copper-content, sinter-forged connecting rods

• New four-cam phasing system with intermediate park technology that enhances efficiency by enabling late inlet valve closing in certain conditions

• All-new, patented “targeted” cooling system that provides strategic cooling of the engine’s hottest areas while simultaneously fostering faster warm-up, which enhances efficiency

• New cylinder heads that enhance combustion performance and include direct injection and feature integrated exhaust manifolds

• Revised, simplified timing drive system with cushioned chain sprockets contributing to quieter engine operation

• All-new oiling system moves the pump inside the block for quieter operation. The two-stage oil pump also enhances efficiency.

“This new architecture leverages the best of Cadillac’s proven, awarded V-6 engine technology and takes it farther with a finer focus on refinement and durability to match its benchmark output and efficiency,” said Bartlett.

A more complete look at the architecture, features and attributes of the new V-6 family is available in the 3.6L release.

Unique foundation

While the 3.0L Twin Turbo is based on the same, all-new architecture as the naturally aspirated 3.6L V-6, it incorporates specific components and features to support the load and cylinder pressure characteristics unique to a forced-induction engine.

Its 86mm bore specification is about 10 percent smaller than the 3.6L, while both engines share an 85.8mm stroke. The smaller bore reduces the size and consequentially the weight of the pistons in the 3.0L Twin Turbo, making the most of the rotating assembly’s geometry to match the quicker rev capability enabled by the low-inertia turbochargers’ quick spool-up.

“With nearly zero turbo lag and a commensurately low-inertia rotating assembly, this engine climbs the rpm ladder and produces power on demand,” said Bartlett. “Its performance is more than just the maximum output – it’s how it is delivered and the new 3.0L Twin Turbo delivers it with smoothness and precision.”

The smaller bores also allow larger water jackets between the cylinders, which helps maintain optimal combustion temperatures across the rpm band and during sustained high-load, max-boost performance.

Additional features unique to the 3.0L Twin Turbo include:

• Lower 9.8:1 compression ratio vs. 11.5:1 on the naturally aspirated 3.6L

• Extreme duty 44MnSiV6 steel crankshaft forging

• The pistons incorporate a specific steel insert in the top ring land to support the turbocharged engine’s higher cylinder pressures

• Large, 36mm intake valves and 29mm sodium-filled exhaust valves enable the engine to process tremendous airflow

• The valves are held at 19 degrees on the intake side and 16 degrees on the exhaust side vs. the 3.6L’s 18 degrees for the intake and 15 degrees for the exhaust

• Valve spring pre-load tension is increased to manage the greater exhaust pressure during peak load performance

• Hardened AR20 valve seat material on the exhaust side is used for its temperature robustness, while the heads are sealed to the block with multilayer-steel gaskets designed for the pressure of the turbocharging system

• Tuned air inlet and outlet resonators, aluminum cam covers and other features contribute to exceptional quietness and smoothness.

Low-inertia turbochargers and vacuum-actuated wastegates

The twin, low-inertia turbochargers’ featherweight titanium-aluminide turbines are used with vacuum-actuated wastegate control for precise, responsive torque production. The titanium-aluminide turbines reduce rotating inertial load by more than 50 percent, compared with conventional Inconel turbine wheels. That means less exhaust energy – which spins the turbines – is wasted in stored inertial loads.

In practical terms, that means the relatively small size of the turbochargers and their lightweight turbines foster more immediate “spooling,” which practically eliminates lag, for an immediate feeling of power delivery. They produce up to 18 pounds of boost (125 kPa).

A single, centrally located throttle body atop the engine controls the air charge from both turbochargers after the temperature is reduced in the intercooler. This efficient design also contributes to more immediate torque response, while reducing complexity by eliminating the need for a pair of throttle bodies.

Unique vacuum-actuated wastegates – one per turbocharger – are used with the Twin Turbo for better management of the engine’s boost pressure and subsequent torque response for smoother, more consistent performance. They are independently controlled on each engine bank to balance the compressors’ output to achieve more precise boost pressure response.

The wastegates also work in concert with vacuum-actuated recirculation valves to eliminate co-surge from the turbos – a condition that can result in dynamic flow reversal, such as the moment immediately after the throttle closes. This overall system integration contributes to the engine’s smoother, more consistent feeling of performance.

Patented low-volume charge-air cooling

Cadillac’s patented, manifold-integrated water-to-air charge cooling system also contributes to more immediate torque response, because the compressors blow through very short pipes up to the intercooler.

With no circuitous heat-exchanger tubing, there is essentially no lag with the response of the turbochargers. Airflow routing volume is reduced by 60 percent when compared with a conventional design that features a remotely mounted heat exchanger.

“It is a very short path from the compressors to the intake ports,” said Bartlett. “The compressors draw their air directly from the inlet box and send their pressurized air through the intercooler immediately for a tremendous feeling of power on demand.”

The charge-cooling heat exchangers lower the air charge temperature by more than 200 degrees F (94 C), packing the combustion chambers with cooler, denser air for greater power. Also, the air cooler system achieves more than 80 percent cooling efficiency with only about 1 psi (7 kPa) flow restriction at peak power, which contributes to fast torque production.

Manufacturing

Both of Cadillac’s new V-6 engines will be produced at GM’s Romulus Powertrain Operations assembly facility, near Detroit, which received a $540-million investment to build the next-generation V-6 engines.

FAST FACT: In 1903, the first production Cadillac motor cars were equipped with a single-cylinder engine rated at 10 hp.

Cadillac has been a leading luxury auto brand since 1902. Today Cadillac is growing globally, driven by an expanding product portfolio featuring dramatic design and technology. More information on Cadillac appears at www.cadillac.com. Cadillac’s media website with information, images and video can be found at media.cadillac.com

[/expand]

—

Every month, there are 1.2 million unique visitors reading YouWheel.com articles. Do you know you can also present your own contents to our enormous reader base? Check our new feature: YouWheel Guest Post. We are looking forward to your submission!

Recent Comments