Index

Why the Lexus LFA is a special supercar – part 1 (carbon fiber technology)

Why the Lexus LFA is a special supercar – part 2 (engine)

When the Lexus LFA went on sale in late 2010 and early 2011, some of its specifications seem to be outdated: for example its V10 engine still uses traditional port injection for the fuels, while the 10-times-cheaper IS250 has already incorporated fuel direct injection for 4 years; and also the LFA is using a single clutch 6 speed automated sequential transmission, while there are plenty of sports cars using a more advanced double clutch transmission.

These indeed are shortcomings of the LFA, caused by the lengthy development cycle for 10 years. The root cause of this delay is mainly due to the R&D management changed their mind to switch from an aluminum body to a carbon fiber material car frame design, in the middle of those 10 years (LFA project starts in 2000 and the decision to use carbon fiber happened in 2005).

Had the LFA went in production 5 years earlier, its specification sheet will look more pleasant to those who criticize the above mentioned shortcomings.

Even with the long development cycle, a lot of LFA’s design and manufacturing technologies are still the most advanced, unique and state-of-the-art, from today’s point of view.

Let’s look at the carbon fiber body first. Historically speaking some of other exotic cars are also using carbon fiber to construct their bodies. Before LFA there is the Mercedes-Benz SLR McLaren, after LFA there is the Aston Martin One-77. But they are still not advanced and well designed as the LFA.

For the SLR McLaren, despite its use of carbon fiber material, it is still very heavy (near 3,900lbs). Had it made of other metals such as aluminum or high strength steels, it is possible that it still would not weight much heavier than this number. The other part is its design of layout – both engine and transmission in front, makes the car nose extremely long. While some folks may like such visually long-nose cars, this design does no good to the handling and performance.

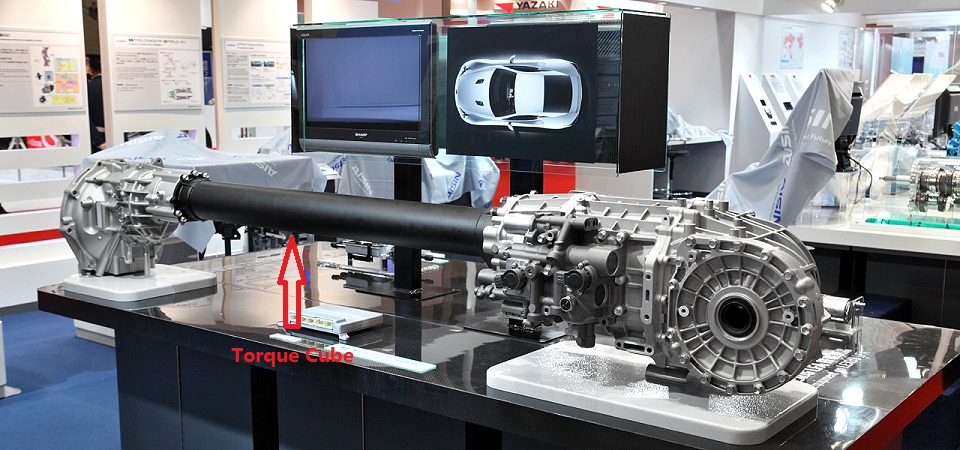

For the One-77, it has similar layout as the LFA. Its engine is placed in the front, and transaxle is in the back. This requires a solid torque tube to connect the engine to the rear transmission. For this layout, the torque tube need to deal with forces in multiple directions. For example, when the driver launches the car, the tube takes the stress of trying to pick up the nose by the engine; If the engine is outputing large amount of torque, there will be a torsional stress along the longitude axis. So the torque tube must be made of something really strong.

One-77’s torque tube is made of magnesium alloy. However, the LFA engineers managed to design and manufacture a carbon fiber torque tube, which is lighter and stronger. As a side note, the 2015 Corvette Stingry Z06’s torque tube is also made with carbonfiber, but it is outsourced to an Australian firm. Please see the below photo, what the red arrow points to is the unique carbon fiber torque tube in LFA’s powertrain.

The layout of LFA is also first-class. Even though it has a V10 engine, looking at its side profile you will see the length ratios among the engine compartment, occupant compartment and the rear body, are in harmonic and suitable scale. It looks quite naturally, no super-long nose, no cramped cabin.

Also for a stronger connection between different carbon fiber parts in LFA, aluminum threads (they call it aluminum collars) are embedded into the carbon fiber parts during forming. So you won’t crack the carbon fiber parts, or weakened its strength when you are tightening up the screws to join them. Each bolt is not torqued with the the normal pneumatic wrench we usually see in shops; instead they use a digital reading and manual torque wrench to do the job. After each bolt, the worker will make corresponding notation on a fact sheet. This means, every bolt on the LFA is documented with detailed data. As far as I know this procedure is still the only one in the automotive industry.

In part 2, we will examine some interesting facts about LFA’s V10 engine, code named 1LR-GUE.

Recent Comments