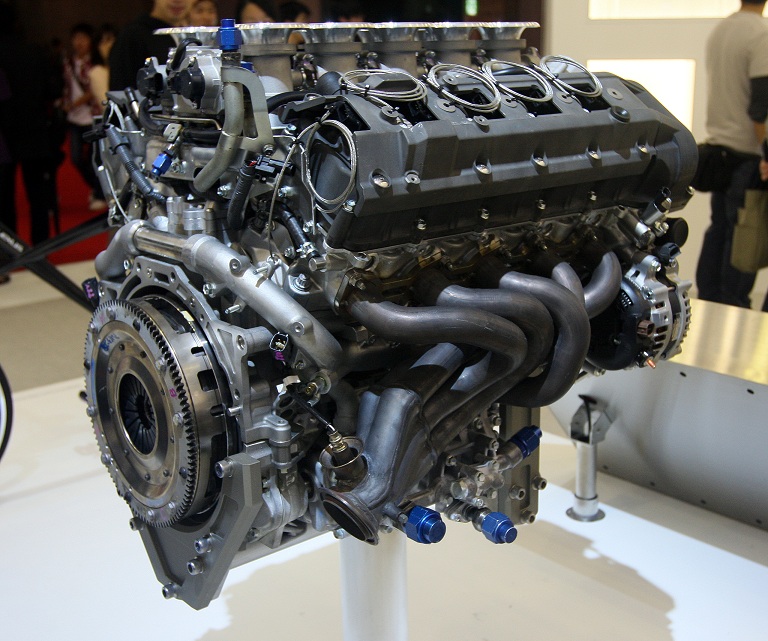

In part 1, we reviewed the body construction of the LFA. Now let us take a look at its heart – the 1LR-GUE 4.8L V10 engine.

Some may criticize it does not has fuel direct injection. However let’s see what is the benefit of using direct injection.

By using direct injection, the internally sprayed liquid fuel can lower the cylinder’s temperature, therefore lower the possibility that the fuel to be ignited by the high engine temperature. Therefore, a higher cylinder compression ratio can be utilized, and the higher compression ratio can thus raises the output and lower fuel consumption. So we see, the main purpose of using direct injection is for raising the cylinder compression ratio.

Even though lacking direct injection, 1LR-GUE’s compression ratio is already reaching 12.0:1, this number is higher than some of the latest direct injection engines. For example the 2GR-FSE (used in 2014 IS350, GS350) compression ratio is 11.8:1, lower than 1LR-GUE. So not using direct injection is not an critical issue for the V10 engine.

Anyway, we can still say: had the 1LR-GUE utilized fuel direct injection, it could achieve higher output. For this matter we must not forget, this engine is designed 10 years ago.

Besides this, 1LR-GUE has some very unique and advanced features. For example, its rocker arms are made with titanium; its intake valves are made with titanium too. Of course some other competitor’s engine also has these features. But 1LR-GUE has one unique thing that nobody has at this time – its exhaust valves are also made with titanium.

Next pay attention to its 9000rpm redline (fuel cut-off is 9500rpm), this is absolutely not a trivial thing. To achieve this, its intake valve train has a very unique design. For most DOHC engine, its valve is usually controlled by the roller finger follower mechanism, the benefit for this is the fuel efficiency. But on the other hand, roller finger follower is not suitable for high revving engines, so most high-redline DOHC engines will use the direct-acting tappet system. However, what 1LR-GUE uses is: the finger follower WITHOUT the roller. This design makes it possible that the size of the finger follower be smaller, much lighter, much stronger, and much more suitable for high rpm redline. To decrease friction, Lexus also apply a DLC coating on the finger follower.

The 1LR-GUE does not have cylinder sleeve, instead the cylinder walls are applied with a thermal spray layer, which significantly lower the friction between the piston heads and the cylinder walls.

This engine also has individual throttle bodies for each cylinder (a total of 10 independent throttle bodies). The whole exhaust system is made of titanium, which cost equals to a Toyota Corolla (yes, the money you can buy a Corolla can only buy a set of exhaust manifolds and muffler for the LFA). From the following photo you can see the titanium made exhaust pipes.

The 1LR-GUE uses a 72-degree V bank angle, which means it has even firing order (balanced firing forces), so it does not require the use of a split-journal crankshaft. The 72-degree V bank design contributes to the special sound signature of this V10 engine (Yamaha contributes help too).

Because of using so many advanced technologies and design, the 1LR-GUE’s size is similar to a V8 engine, and its weight is so light that it is comparable to a V6 engine. With such small size and extremely light weight, it churns out 552hp and 354lb-ft of torque.

Generally speaking even with today’s latest standard, the LFA V10 is still one of the most advanced and uniquely designed engines, which provides top-notched performance.

Recent Comments