Nowadays, plastic is not something unfamiliar in our daily commute cars. We see them in the interior trims, body panels, cowls and even some brackets inside the engine compartment.

Previously we can never think of using plastics in some critical parts which are subject to high loads, excessive heat and demanding stress. But the usage of engineering plastics continues to expand in the auto industry.

One example is the BMW N20 4-cylider turbo engine. For some F30 3-series, the N20 engine comes with a plastic engine oil pan, as shown in the below image. The engine oil pan seals the underside of the engine and holds all of its lubrication oil.

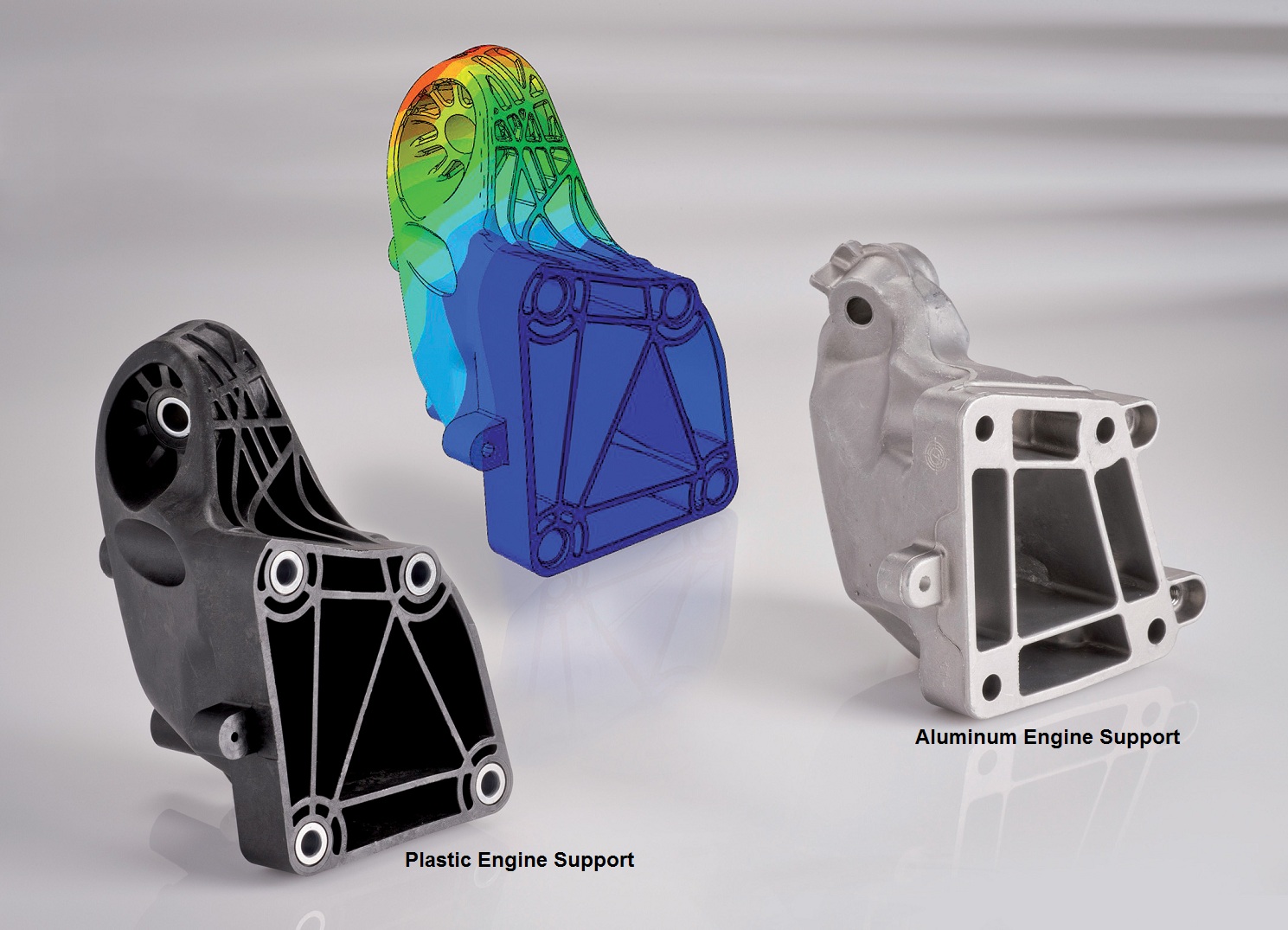

Recently Mercedes-Benz go another step further, by using plastic to make its engine support (which is made with aluminum, previously) for the GL350 BlueTEC diesel SUV. According to its supplier – BASF, the plastic they used to made the engine support, the Ultramid® A3WG10 CR, provides better acoustic damping effect, less heat transmission that can degrade the engine mount’s rubber component, and lighter weight. In the below image, you can see the same part made with aluminum and with plastic.

Below is BASF’s press release about the above mentioned plastic engine support.

World’s First Plastic Engine Support in the New Mercedes GL Class

Daimler is installing the world’s first plastic engine support for the six-cylinder diesel engine used in the new GL Class. Compared to the previous aluminum support, the plastic part offers improved acoustical properties, better thermal insulating characteristics and a definite weight advantage, while being able to withstand the same load. The part, which supports the engine with the aid of the engine mounts, is molded from Ultramid® A3WG10 CR, a highly reinforced specialty polyamide from BASF that has been optimized for high mechanical loads. Joma-Polytec in Bodelshausen assumed responsibility for designing the injection mold and producing the plastic engine support.

Engine support functions and requirements: Static load, continuous load, crash

The torque supports that are already used by various automakers in versions of Ultramid transmit only the tilting moment of the engine. In contrast, engine supports are subject to a permanent load – the engine’s weight – while absorbing in addition the entire engine torque. To date, they have always been made from aluminum.

Acoustics, heat transmission, weight

To replace aluminum in this challenging and also crash-relevant application, the plastic must fulfill demanding mechanical requirements: while Ultramid® A3WG10 CR is very rigid; it was also necessary to demonstrate that it exhibited sufficiently low tendency to creep in the confined space of the engine compartment when subjected to a continuous load. Furthermore, depending on the installation conditions in the engine compartment, the plastic engine support must also withstand high bending moments. The good acoustic characteristics are the primary benefit of the Ultramid engine support over its aluminum counterpart. Thanks to the damping behavior specific to plastic, the new engine support contributes to a more balanced sound.

An additional benefit is that the heat conduction of the plastic is considerably less than that of aluminum. As a consequence, the Ultramid engine support provides better protection from the engine’s heat for the natural rubber engine mounts connected to it, increasing their service life. In the context of the CO2 discussion, a weight savings of over 30% for the plastic part versus the aluminum version is an additional plus.

Simulation for optimization of crash and acoustic behavior

The multitude of tests that the plastic part must pass successfully includes the so-called repair crash, which replicates smaller crashes, and the massive offset crash (offset head-on crash). In the first case, the support must remain undamaged; in the second case, it must fail quickly and in a specific manner to prevent the engine’s entering the passenger compartment.

In addition to checking these requirements in crash tests, BASF already incorporated both cases into the very early development phase of the complex-shaped engine support through use of its Ultrasim® universal simulation tool and predicted the part’s behavior: Ultimate (breaking) loads, strength values under dynamic pulsed loads and crash loads agreed very well with the results of testing and achieved the values required for the aluminum predecessor. It was thus possible to incorporate ribbing to withstand the high loads and satisfy acoustic requirements early on and reduce the number of prototypes.

Recent Comments