In a nutshell, a linear generator (full name: Free Piston Engine Linear Generator, FPEG) is an internal combustion engine that generates electric power directly.

Recently R&D engineers in Toyota has made breakthrough in this area, and presented the concept at the most recent SAE meeting in Detroit.

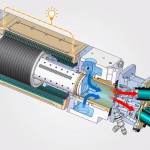

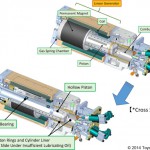

Below are three illustrations from Toyota R&D, that explained the idea briefly.

In a traditional internal combustion engine, the piston’s back-and-forth movement energy are transmitted through the rotating crankshaft. Despite this, the FPEG does not have a crankshaft. The kinetic energy generated by burning the fuel and caused the back-and-forth movement of the piston, is converted to electric power by the Principle of Electromagnetic Induction, because of movement between the permanent magnet on the piston body, and the coil around the cylinder chamber.

The current Toyota prototype FPEG works on a two-stroke cycle.

One question you may ask is: since there is no crankshaft, the piston will be pushed backward during the power stroke, but how come it can move forward? The answer is simple: a gas spring is installed at the back of the piston to provide the force to push the piston forward during the exhaust stroke.

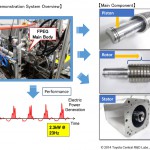

The proposed test FPEG can generate 13hp of power, according to Toyota, a pair of this linear generator will have enough output to let a compact sedan cruise at 75mph.

More technical oriented reader may find that with only one piston in the FPEG, there will be serious vibration issue. But this can be completely solved by using a pair of horizontally-opposed placed FPEG, where the vibration force from one piston movement can be completely cancelled out by the piston on the other side.

Even though there are still considerable gaps between the Toyota prototype and a production practical product, one cannot denied that the FPEG has great potentials in the automotive industry.

Recent Comments