Continuously Variable Transmissions (CVT) have two major types: one does not use a belt to transmit power, such as Toyota’s Hybrid Synergy Drive, which uses mechanical gears; another type of CVT uses belts connecting two pulleys.

The first type has the advantage of real mechanical hard connections, high efficiency and high capacity (can handle large torque), but one limitation is that the Toyota Hybrid Synergy Drive, its mechanical structure can only be used in hybrid powertrains, that transmission will not work in a traditional internal combustion engine powered car.

For the belt type CVT, it can be used in all cars with different types of power sources, and it has unlimited gear ratios; but since it depends on the friction between the belt and the pulley to delivery energy, its ability to transmit torque is limited; and its efficiency under high load is not as good as other traditional automatic transmissions.

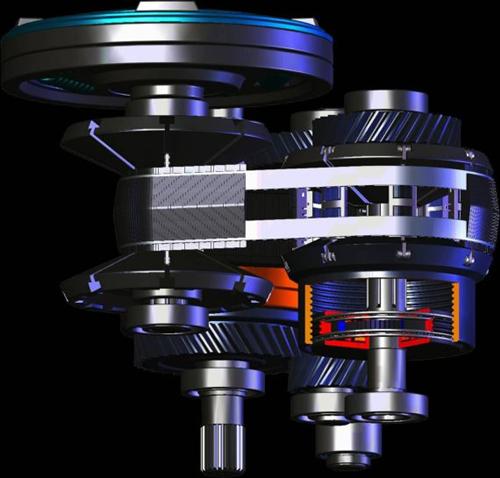

Recently, VIT Automobile Science and Technology Ltd, a company specialized in transmission technology, based in Beijing, China, released some information about their latest product: moveable teeth CVT (they called it “HN-CVT”). Below is one of its production units.

The HN-CVT combines the benefits of the above two mentioned CVTs. According to VIT, they already has one model of the HN-CVT that with torque rating of 738 lb-ft (1000Nm). What’s more, the HN-CVT has an astonishing high efficiency ratio of 96% (it only loses 4% of the energy coming from the engine flywheel, before putting the power to the car’s wheels). For comparison, traditional automatic transmissions usually have an efficiency ratio between 80% – 90%.

The principle of the HN-CVT (moveable teeth CVT) is based on the fundamental of how a car transmission works. Regardless what type of a transmission is, they all work in this way: the input side is paired to a gear with a certain amount of teeth, and the output side is paired to another gear with another amount of teeth. If the tooth amount of the two gears are different, the input side and the output side will rotate at a different speed.

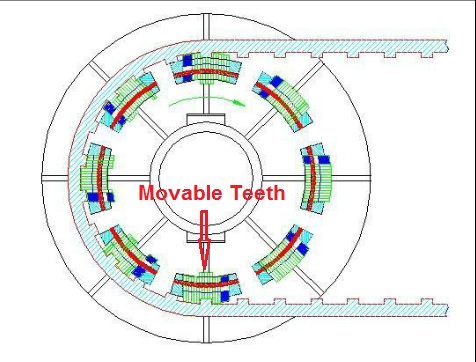

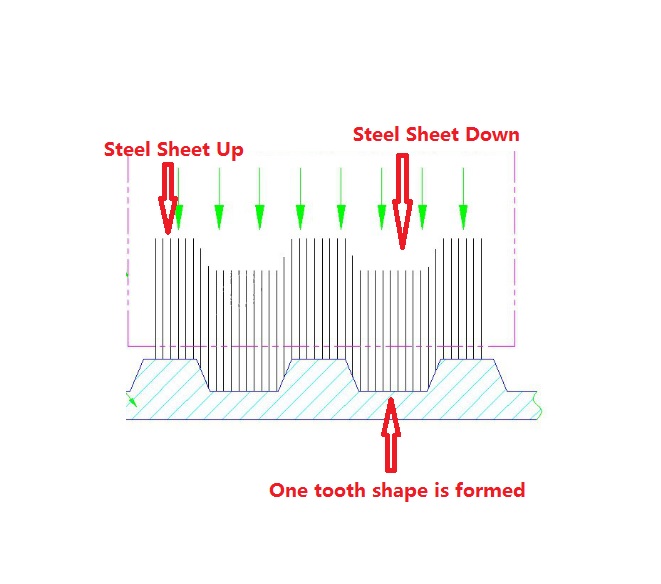

For the HN-CVT, it still has a belt. But different from other CVTs, the belt has fixed teeth on it. The HN-CVT also has a pulley, but it is a special pulley: it has many small steel sheets packed on its surfaces. Those small sheets can go up and down individually (controlled by the transmission ECU). If some sheets goes up at the same time, then the convex shape it formed becomes one tooth.

For all the steel sheets on the pulley, the transmission ECU can control their action to form multiple convex shapes, therefore it essentially becomes a gear. The key point is: by controlling the combination of up-down shape of the steel sheets, it can become a gear with any tooth amount it wants. So the fixed-amount-tooth belt meets the variable-amount-tooth pulley, and different transmission ratio can be realized. Below is an illustration.

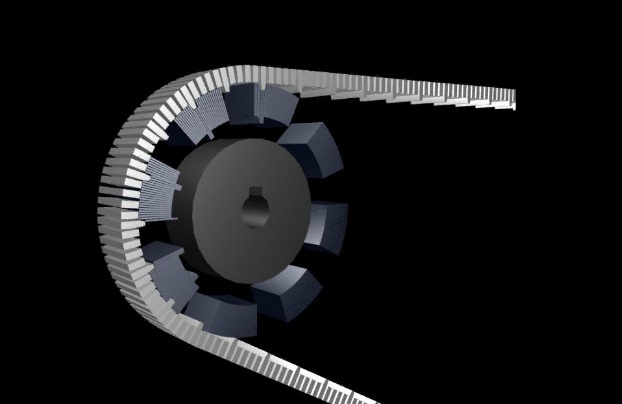

And this is a 3D CAD image.

Because it is tooth-to-tooth contact, this transmission can handle large amount of forces without causing sliding and frictional wear.

VIT has very ambitious business and marketing plans for the HN-CVT. According to the company, they have patents in US, Canada, Europe Union (including 13 countries), Japan, Korea, Australia and India, covering 80% of the world’s automobile industry sharing.

The HN-CVT has unmatchable mechanical performance, and also cost advantage. VIT said its HN-CVT costs 20% – 50% less than other comparable transmission units.

Because of such advantages, according to our insider information, one US major automobile company is already cooperating with VIT to develop dedicated products with this technology. Since there are only three major car company in the states, the one who is working with VIT must be GM, or Ford, or Chrysler. From the source, we know we will see the HN-CVT in some production passenger car in 2017 – 2018, and some luxury cars may also use this transmission as early as 2020.

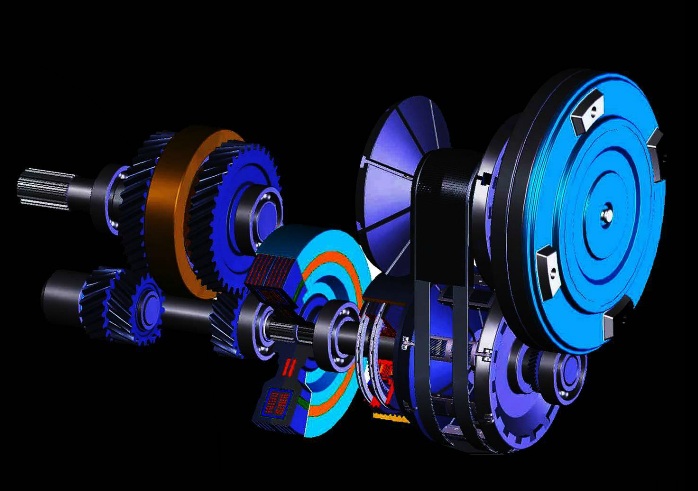

Below are some images of the HN-CVT internal construction. If this transmission can reach the mass production stage, I am sure this will be a big milestone in the auto industry.

Feel free to leave a question or share an opinion in the comment box below.

YouWheel.com is dedicated to bringing you the best automobile news, reviews,tips, test drives & technical talk, throughout the auto industry. Visit our Member Center & Blogs at http://youwheel.com/welcome/ Sign up and become a Free YouWheel.com Member today!

Recent Comments